Industrial Aluminum Profile Production Process

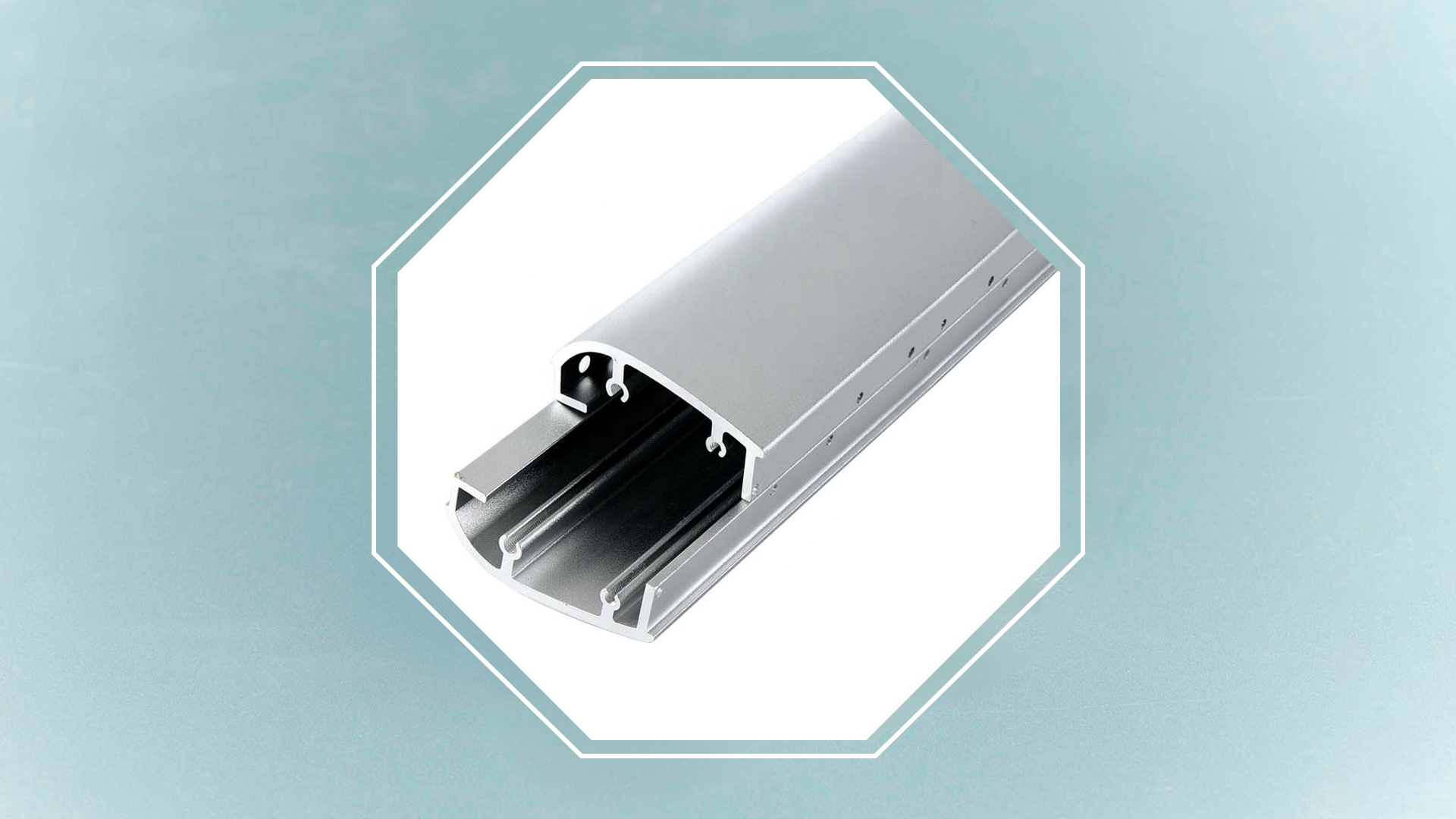

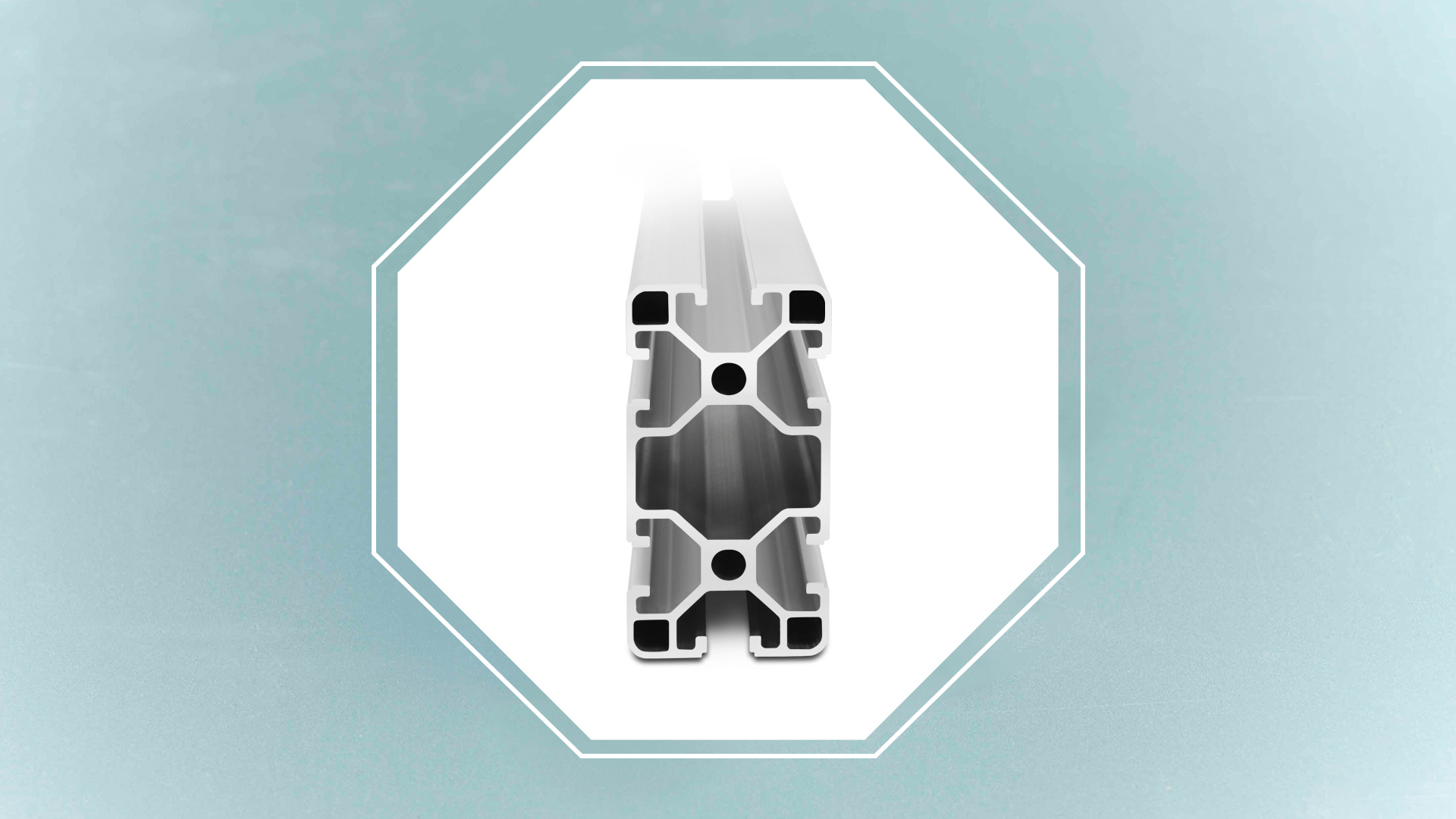

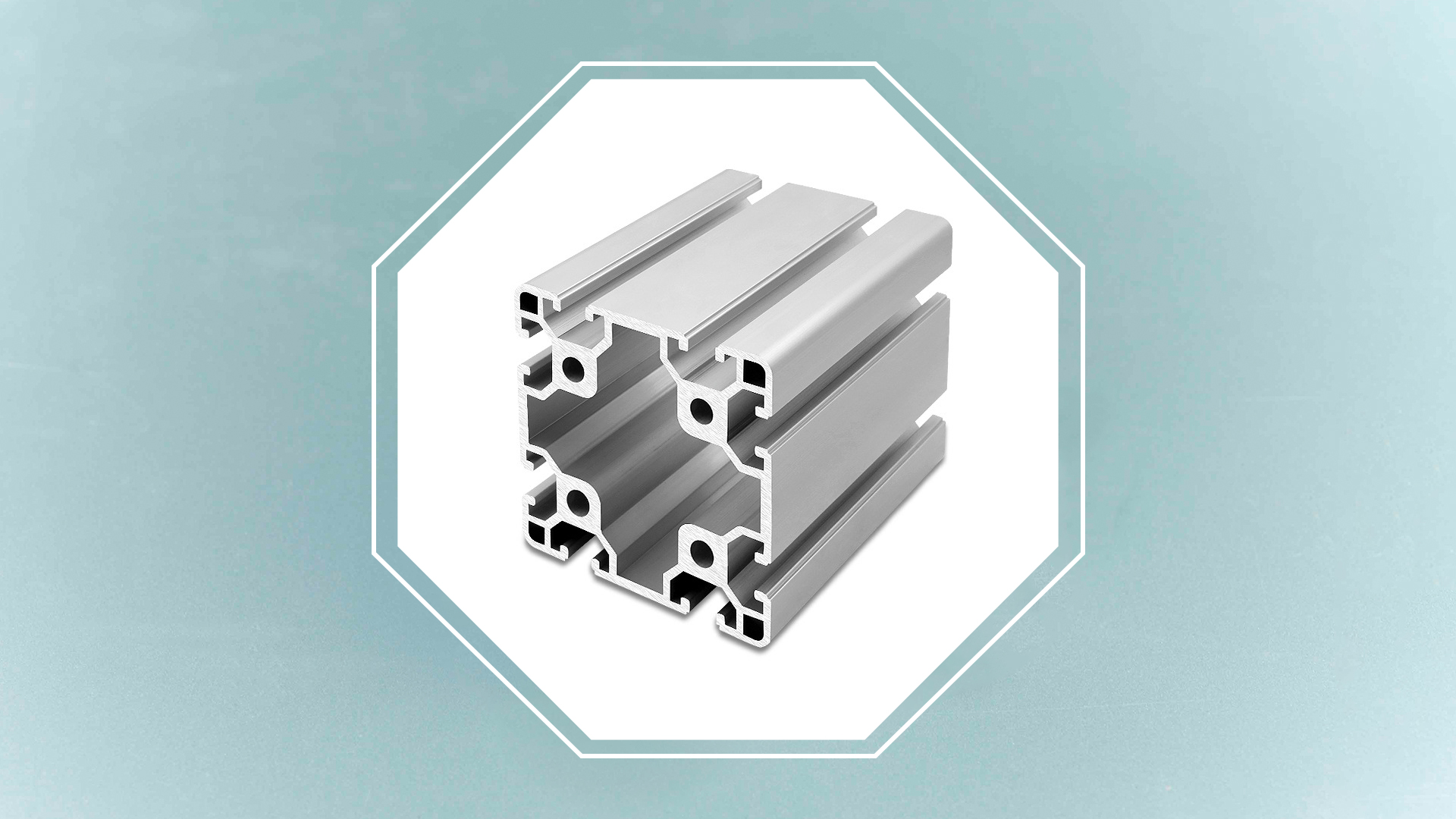

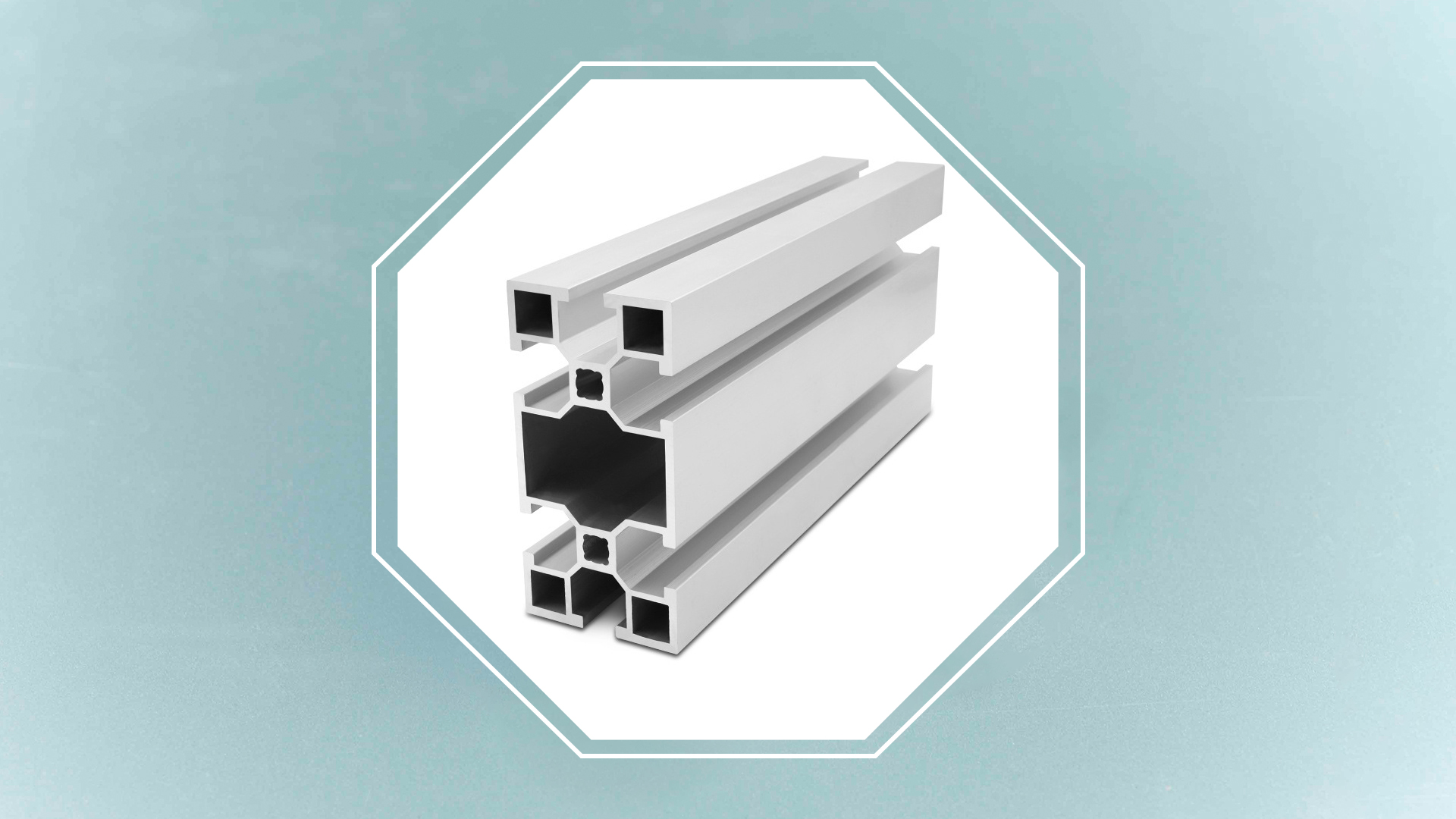

Industrial aluminum profiles refer to aluminum products that have undergone a series of complex processing and are widely used in fields such as construction, transportation, and mechanical manufacturing. The manufacturing process requires efficiency and precision, which directly affects the quality and efficiency of the product. The following is an introduction to the production process of industrial aluminum profiles.

Firstly, the production process generally consists of several steps, including prototype design, material selection, raw material processing, surface treatment, machining, assembly, and packaging. Prototype design is the prerequisite for industrial aluminum profile production. It involves determining material specifications, section dimensions, deformation, and hardness based on customer requirements and product usage environment. Additionally, feasibility analysis and evaluation of product structure and manufacturing difficulty need to be conducted based on actual production conditions and technological capabilities to provide basic data for process development.

Secondly, material selection directly affects the physical and chemical properties of aluminum profiles, which in turn impact mechanical performance, corrosion resistance, and maintenance aspects of the products. Depending on the product application environment and requirements, suitable alloy materials such as 6063, 6061, 6082 aluminum alloys are chosen for industrial aluminum profile production. The chemical composition and mechanical properties of the chosen alloys are carefully controlled to ensure product quality stability and uniformity.

Thirdly, raw material processing is a crucial step in the manufacturing process and involves various methods such as forging, extrusion, and casting. Among them, extrusion is the most commonly used method, where the softened aluminum billet is extruded under pressure to achieve the desired product shape and dimensions. To improve product quality and production efficiency, variables such as extrusion speed, temperature, pressure, and mold wear need to be strictly controlled to prevent defects such as foreign objects and bubbles.

Finally, surface treatment, machining, assembly, and packaging are the stages where aluminum profiles undergo detailed processing and become finished products. For example, surface treatment through methods like spraying, anodizing, and heat transfer can enhance the appearance, color, and corrosion resistance of the products, thus increasing their market competitiveness. By following this complete process, high-quality and cost-effective aluminum profile products can be produced.